The THREE rates you need to know about for Single Spot spraying

Dave Young

When you select Single Spot, THREE different rates/ha come into play. Here is what you need to know about them.

What most people miss when it comes to Spot Sprayers that enable isolated activations (Single Spot) is that there are THREE different rates/ha in the mix.

1. Spray-width rate (nozzle footprint)

As you probably know by now, rates per hectare calculations for isolated nozzles use the spray width on the ground in place of the nozzle spacing in the calculation. The result is usually somewhere around half the rate of the same nozzles if they were overlapping. i.e. from your normal nozzle chart.

If you are using even fan nozzles, this is the rate you will be applying as the spray is distributed evenly across the full footprint.

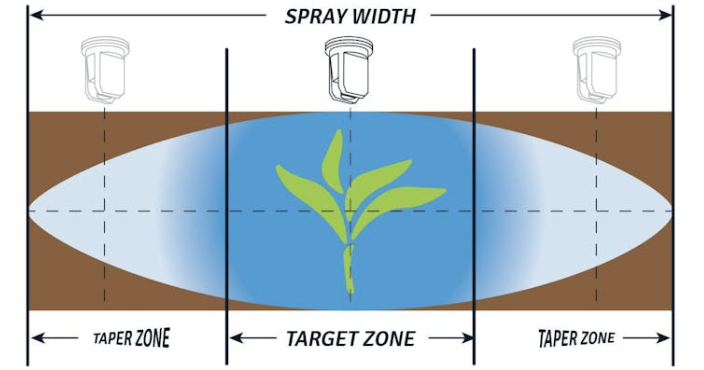

2. Target Zone rate (the fat bit of the tapered fan)

This is where we are using an elliptical tapered fan nozzle, which has more volume in the centre of the nozzle than at the tapered edges. To define the Target Zone, we use the nozzle spacing centred on the nozzle (50cm nozzle spacing, the Target Zone is 25cm either side of the nozzle).

This is really efficient as we get the maximum volume on the target, and any weeds falling in the taper zones are in the Target Zone of the adjacent nozzle.

The Target Zone rate, is the rate we batch up our chemicals for. We have even developed a batching App (BatchApp) to help you with that and post job reporting.

3. Overlapping rate

When adjacent nozzles do engage, they will overlap each other and the application rate reverts to conventional nozzle spacing calculation.

**The overlapping rate also doubles as the controller setting.** Spray controllers on almost all integrated SP/Spot Sprayers can only display rates calculated on the nozzle spacing. **Use the overlapping rate as your controller setting** and you will achieve the desired rate for isolated activations automatically.

To illustrate the point, here are some numbers I did yesterday for a researcher doing Green on Green trials. They show the three rates quite clearly when comparing the CFLD-XC4002 and CFLD-XC4003 at 16.5 km/h, 70cm nozzle height and 25cm nozzle spacings.

An interesting observation here is that increases in pressure result in a decreasing percentage volume in the Target Zone. That is the reason why we have settled on 3 BAR as the optimum application pressure in our Apps and online calculators. Excessive pressure can be counter productive!

I trust that you will find this information informative and useful in your single spot spraying journey.

If you need help with spot spray nozzle selection, I recommend you pay a visit to App Central where you can find an App for your own spot sprayer integration. If you need help once you get there, just give me a ring.

Thanks and regards,

Dave Young

1800 920 312